Home > Product > Master Batch

Master Batch: Industrial

Industrial masterbatch mainly handles preventing food, products, etc. from the external environment. It plays a role of packing so that the original state can be preserved.

The function required in industrial film

1) Slip Performance

2) Anti-blocking

3) Anti-static

4) Anti-fog

Functional masterbatch to impart functions such as, etc. to industrial films.

Anti Fog MasterBatch for packaging film

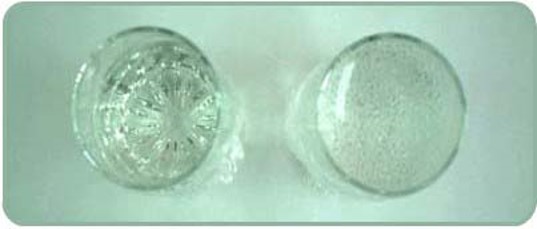

The anti-fog M/B for packaging film is a functional masterbatch that prevents water droplets from forming on packaging films, which is caused by the evaporation of moisture included in the films. This product also makes the inside of the films look transparent.

- Increase visibility and light transmission rate with excellent surface wettability.The anti-fog M/B for food wrap added to plastics moves to the film surface and reduces the surface tension of water to improve the visibility and light transmission rate inside plastic films.

- Prevent the defects where rolled films do not loosen well. additive ofthe anti-fog M/B, is suitable for food packaging as it is extracted from vegetable oil and used as a raw material for high-quality food packaging.

- Product specifications & properties

| GRADE | - |

|---|---|

| Appearance/Color | Pellet / White |

| Moisture contents | Max 0.3% |

| Package | 25kg/bag |

| Standard blending ratio | Adding 5%~10% M/B when processing plastic film. |

Anti Fog MasterBatch for Wrap Film

The anti-fog M/B for packaging film is a functional masterbatch that prevents water droplets from forming on packaging films, which is caused by the evaporation of moisture included in the films. This product also makes the inside of the films look transparent.

- Increase visibility and light transmission rate with excellent surface wettability.The anti-fog M/B for food wrap added to plastics moves to the film surface and reduces the surface tension of water to improve the visibility and light transmission rate inside plastic films.

- Prevent the defects where rolled films do not loosen well. additive ofthe anti-fog M/B, is suitable for food packaging as it is extracted from vegetable oil and used as a raw material for high-quality food packaging.

- Product specifications & properties

| GRADE | - |

|---|---|

| Appearance/Color | Pellet / White |

| Moisture contents | Max 0.3% |

| Package | 25kg/bag |

| Standard blending ratio | Adding 5%~10% M/B when processing plastic film. |

Freshness MasterBatch

Freshness M/B is a functional masterbatch in which films for packing agricultural products absorb ethylene gas generated fromvegetables and fruits to maintain the freshness of agricultural products.

- Absorb ethylene gas. Ethylene gas is produced during the biosynthesis of cells and microbes in plants, which is the main cause of degrading the quality of agricultural products because it promotes the aging of the products.

- Increase the concentration of carbon dioxide by lowering the oxygen content in packing materials.This M/B is used to remove oxygen from food packaging at the time of packaging to prevent the occurrence of mold, which is the cause of food spoilage, and to increase the retention period of food during the distribution process.

- Product specifications & properties

| GRADE | - |

|---|---|

| Appearance/Color | Pellet / Light brown |

| Moisture contents | Max 0.3% |

| Package | 25kg/bag |

| Standard blending ratio | Adding 5%~10% M/B when processing plastic film. |

| Minimum order quantity | 5 Ton |

Anti Blocking MasterBatch

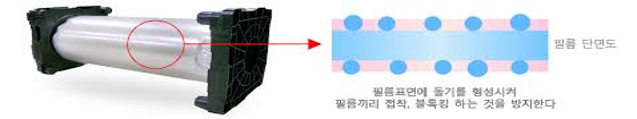

Anti-blocking M/B is a functional masterbatch that prevents blocking phenomenon, where plastic films stick to each other, by making fine particles on the surface of the plastic films.

- Prevent blocking phenomenon where plastic films stock to each other. A blocking phenomenon means that a film or sheet with a smooth surface is not able to be separated from each other. Suchblocking causesdiscomfort when processing or using products, so Anti-blocking agent (A/B) can be used to resolve this problem. In addition, this A/B agent is an easy-to-use additive mixed with resins when producing films or sheets.

- Prevent the defects where rolled films do not loosen well. Blocked films do not loosen well and generate noise when they are released. In addition, this causes defective products when such films are packaged automatically due to difficulties in high-speed processing.

- Product specifications & properties

| GRADE | - |

|---|---|

| Appearance/Color | Pellet / White |

| Moisture contents | Max 0.3% |

| Package | 25kg/bag |

| Standard blending ratio | Adding 2%~5% M/B when processing plastic film |

Slip MasterBatch

Slip M/B is a functional masterbatch that improves the processing and workability of films by making the surface of plastic films smooth and preventing the phenomenon of blocking between films.

- Protect the appearance of films by making it smooth during plastic film processing. This M/B improves the processability of agricultural films by making the flow of high-molecular resin smooth during the processing and protects and polishes the appearance of the films by reducing friction with metal.

- Improve workability as each plastic film gets slippery. Improve workability in packing boxes and rolls as each plastic film gets slippery.

- Product specifications & properties

| GRADE | - |

|---|---|

| Appearance/Color | Pellet / White |

| Moisture contents | Max 0.3% |

| Package | 25kg/bag |

| Standard blending ratio | Adding 2%~5% M/B when processing plastic film |

Processing Aid MasterBatch

Process M/B is a functional masterbatch that prevents the phenomenon of “Sharkskin” from occurring on the surface of films due to the poor flow of plastic materials during the processing of plastic films.

- Prevent melting damages of films on extrusion die due to sharkskin. If the melting temperature is too low or the viscosity of melts is too high, the sharkskin occurs on the surface of plastic products in an extruder die during extrusion, or the products lose surface luster. However, this can be prevented by adding a small amount of process masterbatch.

- Improve product appearance by advancing bubble stability, reducing haze and improving gloss. The smooth extrusion of melts from an extrusion die improves bubble stability and reduces friction between the metal and themelt in the extrusion die surface. Thereby this can reduce haze of films and improve gloss to enhance the appearance of products.

- Product specifications & properties

| GRADE | - |

|---|---|

| Appearance/Color | Pellet / White |

| Moisture contents | Max 0.3% |

| Package | 25kg/bag |

| Standard blending ratio | Adding 2%~5% M/B when processing plastic film |

Anti Oxidant MasterBatch

Anti oxidant M/B is a functional masterbatch that prevents plastic materials from oxidizing and dissolving by heat inside themolding machine during the molding process of plastic products.

- Prevent the quality degradation of plastic materials with the best combination of the first and second antioxidants. This M/B protect polymers by acting as a primary antioxidant that functions as a radical scavenger used to protect the final products and as a peroxide decomposer during the processing. The M/B also protects plastic materials with the optimal combination of secondaryantioxidants, which prevents color changes in organic polymers that are prone to oxidation.

- Product specifications & properties

| GRADE | - |

|---|---|

| Appearance/Color | Pellet / White |

| Moisture contents | Max 0.3% |

| Package | 25kg/bag |

| Standard blending ratio | Adding 2%~5% M/B when processing plastic film |

Korean

Korean